Metal-clad (MC) cable is one of the essential wiring methods commercial electricians use in their daily work. This Chapter 3 wiring method is approved for use in dwelling units and "other than" building types (e.g., commercial, health care, and industrial). This article will give apprentices practical information on industry-recommended practices, installation tips, and NEC guidelines (Art. 330) for the correct application and use of MC cable (Type MC).

The metallic corrugated jacket of MC cable is constructed of interlocked corrosion-resistant steel or aluminum that provides electricians just the right amount of flexibility and abrasion resistance when pulled through wood or metal studs, nailed to joists, or strapped to the surface of walls and ceilings. MC cable is manufactured in various styles, colors, conductor sizes, and configurations. You can find customized cable configurations for specific purposes (e.g., fire protection, audio/video, health care equipment, and harmonic noise reduction).

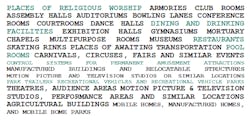

To help resolve harmonic noise problems, the cable may contain either a single grounded conductor sized 150% to 200% of the circuit conductors (super neutrals) or multiple grounded conductors. MC cable can be used in, but is not limited to, dwelling units and the following Chapter 5 special occupancies (see image below).

Understanding cable design, description, and identifiers

MC cable has a distinctive marker tape (print legend) under the armor that typically includes the following information at intervals of 24 in. or less:

- Voltage rating (maximum voltage 600V to 2,000V);

- Size and number of conductors (remember, do not count the ground wire);

- Conductors in 18 AWG to 2,000kcmil copper, or 12 AWG to 2,000kcmil aluminum or copper-clad aluminum;

- Optional markings for special applications (e.g., hospital grade, direct burial, cable tray use, etc.);

- Wire insulation type and designation (e.g., THHN, THWN, XHHW);

- Manufacturer’s name;

- Time and date it was manufactured; and

- Temperature rating.

MC cable typically has a fibrous (paper wrap) covering that consists of 30-pound paper saturated with a preservative and a moisture-resistant compound that reduces abrasion on the conductors when the cables are being pulled. The neutral (grounded circuit) conductor within MC cable is typically white or gray, or it can have a conductor with three continuous white stripes throughout its entire length.

It may also contain an insulated equipment grounding conductor (EGC) that is green (with or without one or more yellow stripes if it is a multi-circuit cable). MC cables are available with multiple grounded and ungrounded conductors; the cable design can vary based on the electrician's needs.

The anti-short

MC cable is constructed to allow an insulated red bushing (anti-short) to be inserted between the conductors and the metallic (armored) jacket at each armor termination to protect the conductors from their sharp edges. When you purchase a coil (250 ft.) or a spool (1,000 ft.) of MC cable, there is typically a packet of anti-short bushings supplied with the wire.

It is a trade practice to install anti-short bushings at each cable termination at panels, junction box connections, equipment connections, etc. The bushing must be fully inserted so the flange on the bushing comes in contact with the armor’s edge.

Anti-short bushings are optional; the NEC does not require them. However, fittings or connectors used with MC cable must be provided with a smooth, rounded end stop to prevent the wires from being damaged by the armored jacket when passing wires to the end stop. In addition, some MC cable fittings may include a red anti-short (insulated throat); these are acceptable in place of a separate anti-short.

The MC cable jacket is an acceptable grounding conductor

Depending on the cable construction or application, the jacket armor assembly of MC cable is an acceptable EGC per NEC Chapter 2, Art. 250. In addition, some cables have a supplemental bare silver wire used for redundant grounding of the jacket; this ensures continuity if the jacket breaks, becomes oxidized, or corroded.

You can use it here and there (uses permitted)

The uses permitted list is not all-inclusive. Type MC cable is rated only for dry locations, ones generally not subject to dampness or wetness. Dry locations may only be temporarily subject to dampness or wetness, "as in the case of a building under construction," which will only be temporarily exposed to dampness. The metallic jacket insulation used is not suitable for wet locations, so do not use it outside — or anywhere it will be exposed to:

- Installations underground;

- In concrete slabs or masonry in direct contact with the earth; and

- In locations subject to saturation with water or other liquids (e.g., vehicle washing areas; unprotected locations exposed to weather).

MC cable can only be used in wet locations when coated with a PVC jacket that will provide added durability. The insulated conductors under the metallic covering are listed for use in wet locations as well. PVC-jacketed MC cable can be directly buried and used in wet locations or encased in concrete.

MC cable can be used for services, feeders, and branch circuits in the following conditions:

- For power, lighting, control, and signal circuits;

- Exposed or concealed;

- In any raceway;

- As aerial cable on a messenger;

- In plenums, spaces used for environmental air; and

- Under raised floors of computer rooms.

Please do not use it here (uses not permitted)

MC cable must be used/terminated with fittings identified for such use. When connecting cable to boxes, cabinets, or other equipment, do not use NM cable connectors or expose MC cable to physical damage. Do not expose the metallic sheath to destructive corrosive conditions (e.g., strong chlorides, caustic alkalis, or vapors of chlorine or hydrochloric acids) unless the cable is rated, listed, and resistant to these conditions or environments.

Do not put it in cinder fills, drainage-promoting fill material typically used around the foundation perimeter of a building or home. Cinder fill is where the land was built up or filled using the cinders from coal-burning furnaces; when cinders get wet, an acid is formed that can destroy raceways and metallic cable jackets. Cinders were also used in lightweight concrete to fill masonry blocks.

Disclaimer

How a wiring method is permitted to be used in a building is ultimately up to the Authority Having Jurisdiction. First, verify the edition of the NEC that has been adopted in the municipality, borough, or state you are working within. In Pennsylvania, where I live, there is no single edition of the NEC enforced; there are different editions of the NEC used throughout the state in the various counties, boroughs, and cities.

Jurisdictions such as Maryland, Delaware, and New Jersey have a statewide adoption of one edition of the NEC. Some jurisdictions may also have local electrical codes that may supersede the NEC guidelines. In some instances, inspectors may also have different interpretations of the rules.

Harold De Loach, a master electrician and electrical trainer/instructor, is the founder of The Academy of Industrial Arts (www.taia-school.com) in Philadelphia. With more than 30 years of experience in the field, he will be writing regular exclusive content for E-Train and can be reached at [email protected].